author:ZMORelease date:2024-06-22Number of visitors:577

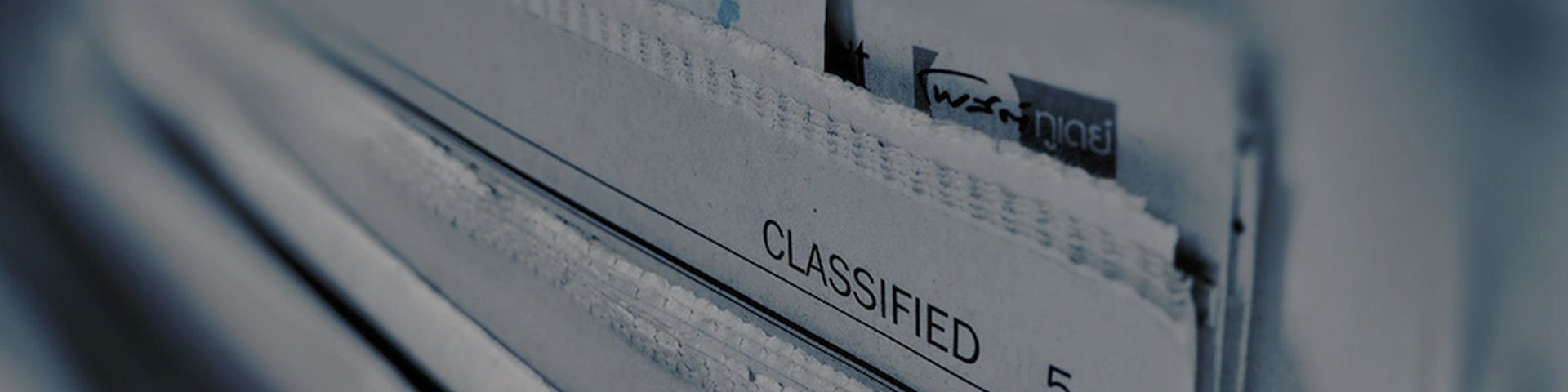

COB package (Chip-on-board) is a packaging method that pastes the Chip directly on the printed circuit Board (PCB), while the traditional packaging method is usually to weld the chip to the PCB. The main difference between the COB package and the traditional package is the way the chip is fixed, and other differences that arise as a result.

First, COB packaging has a higher degree of freedom than traditional packaging. The chips in the traditional package are usually processed and welded separately on the production line, while the COB package is to paste the chip directly on the PCB, which can eliminate the separate chip welding process, but also greatly improve the freedom of assembly.

Second, the COB package has better heat dissipation performance. The chip in the traditional package is welded to the PCB, and the heat dissipation mainly depends on the heat sink on the surface of the chip.

The COB package is to paste the chip directly on the PCB, and the back of the chip is directly in contact with the PCB, which can better conduct the heat out and improve the heat dissipation performance.

COB packaging also has some problems. First, the materials and processes used in COB packaging can be complex, which can lead to higher manufacturing costs.

In practical applications, the choice of using COB packaging or traditional packaging needs to be determined according to specific needs and conditions. If higher assembly freedom and better thermal performance are required, COB packaging is an option.

There are some common issues to be aware of when using COB encapsulation. First of all, it is necessary to ensure that the quality and process of the PCB meet the requirements, otherwise it may lead to problems with the chip. Secondly, the quality and reliability of the materials and adhesives used need to be guaranteed to ensure the stability and reliability of the package. In addition, the chips and heat sinks in the COB package need to be checked and cleaned regularly to ensure good heat dissipation performance.

In addition, because the coefficient of thermal expansion between the chip and the PCB in the COB package may be different, it may lead to problems such as stress concentration or fatigue failure during the thermal cycle. Therefore, corresponding measures should be taken to reduce the impact of these problems in practical applications.

In short, COB packaging and traditional packaging have advantages and disadvantages, and it is necessary to choose which packaging method to use according to specific needs and conditions.

precontent:No Information

nextcontent:No Information

Monday to Sunday 9:00-18:30

Mailbox:sales@zmoled.com

Address:Building B, Emmett Science Park, Luorent Community, Shiyan Street, Baoan District, Shenzhen